Optimizing Wind Fence Outcomes with CFD Technology

Wind fences play a pivotal role in many industries worldwide through effective dust suppression and protecting sites and workers from the effects of strong winds. The development and design of an effective wind fence is more than just fence size, placement, and material porosity. It also must take into consideration other facets including topography, wind speeds and directions, soil composition, climate, and geographical location. This is where computational fluid dynamics or CFD becomes beneficial. CFD is a powerful tool used by engineers to simulate the flow of fluids, optimize structural shape, and enhance the overall effectiveness of the wind fence or windbreak. In this blog, we will explore how CFD modeling unlocks new levels of accuracy and performance in wind fence design leading to improved outcomes and return on investment.

Understanding Wind Fences & Their Impact

Wind fences, also known as windbreaks, are constructed by erecting a porous material to shield an area from the effects of strong winds as well as mitigating dust generation and transport. The porous material allows a small amount of wind to pass through creating a “sheltered zone” on the leeward side of the fence. The sheltered zone in a perfect world can result in a reduction of wind speeds by upwards of 85% and a decrease in fugitive dust by almost 90% as compared to an unprotected situation. Realistically, a wind fence that results in a 70% or more reduction in wind velocity and dust is considered good control although the exact reduction is dependent on the particular site and unique variables involved. Wind fences purposely utilize porous material as this dramatically reduces the creation of turbulence and wind eddies that are typically seen as wind interacts with a solid barrier as the air that passes through the porous barrier effectively equalizes the differential pressure on either side 1. The size of the “sheltered zone” on the leeward side of the fence is dependent on the height and specific design of the wind fence. Note that an efficient wind fence is not a one-size-fits-all structure.

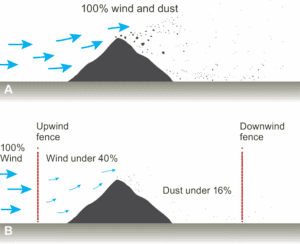

Wind fences typically function via two modalities: upwind fences and downwind fences. When the wind is blowing relatively perpendicular to the wind fence, the velocity of the incoming winds is drastically reduced on the leeward side. This is referred to as an upwind fence. Alternatively, a downwind fence operates a “catch” fence to intercept dust particles that would otherwise disperse. Dependent on the direction and prevalence of the winds, an upwind fence may function as a downwind fence and vice versa. The image below illustrates the effect of a wind fence on wind speeds and dust control as well as providing an example of how upwind and downwind fences function. Wind fences are critical in many industries including mining, power generation, solar energy, construction and bulk material handling. Industries rely on wind fences to improve operational efficiency, comply with environmental regulations and reduce costs associated with dust control and product loss.

Wind fences are critical in many industries including mining, power generation, solar energy, construction and bulk material handling. Industries rely on wind fences to improve operational efficiency, comply with environmental regulations and reduce costs associated with dust control and product loss.

For more detailed information on how a wind fence works, visit our website here or reach out directly to one of our experts at info@weathersolve.com.

What is Computation Fluid Dynamics (CFD)?

The field of Computational Fluid Dynamics is expansive and complex. CFD uses fluid dynamics and mathematical analysis to predict the behaviour of liquid and gas flow within an environment. The fundamental basis of the majority of CFD problems is the Navier-Stokes equations 2. Named after the French engineer and physicist Claude Louis Navier and Irish physicist and mathematician George Gabriel Stokes, the Navier-Stokes equations describe the motion of viscous fluid substances and “mathematically express momentum balance for Newtonian fluids and make use of conservation of mass” 3 . In other words, these equations are the “rules” that govern fluid motion and allow scientists and engineers to solve complex fluid dynamic problems. To put in simply, CFD analysis looks at a specified area and solves millions of little flow equations, assigning probabilities to the results and then solves millions more equations for the next second in time to create expected flow and dispersal patterns for a given set of initial conditions. These initial conditions are then adjusted to determine how the fluid will behave in different situations or conditions and the process is repeated. The calculations are so complex that even incredibly powerful computers may take upwards of 24 hours to produce a single snapshot of information and are generally conducted by specialists in the field. The complete simulation may take more than a month of continuous computer time running 24 hours a day, 7 days a week. With this in mind, it is important to be mindful of claims of “CFD analysis” at significantly lowered costs or as an ad value inclusion as these “analyses” may use low level calculations that will have matching levels of unreliability in their results. As the old adage says “you get what you pay for”.

In the case of wind fences, CFD calculations allow for the optimization of wind fence design and performance by studying exactly how the fluid, in this case air, will behave at a specific site or location. CFD simulations offer solutions to fluid dynamics and engineering problems and are applicable in a variety of industries including aerodynamics, hydrodynamics and thermodynamics.

CFD typically involves the following steps:

- Pre-processing – Defining the problem, creating a model and mesh generation. Mesh generation is the discretization of the domain of interest. Discretization is the “process of dividing a geometry into finite elements to prepare for analysis”5. Mesh generation is the process of breaking down a larger area into smaller more manageable chunks. Take for instance the area surrounding a wind fence. The area may be complex and contain buildings, equipment and other topographical considerations. In CFD, this area is divided into smaller, more simplistic shapes such as tiny cubes or triangles. By doing so, this allows the computers to model fluid flow through analysis of complex geometries and boundary conditions to illustrate what is happening at each small shape. This information is then pieces back together to determine what is happening in the area as a whole, similar to a jigsaw puzzle.

- Solution Derivation – Using computers, calculations of the pre-processing datum are analyzed using CFD solvers and numerical solution methods.

- Post-processing – Visualization and analysis of the results.

- Verification – CFD results are compared to the real-world results to fine-tune inputs.

Why Use CFD to Optimize Wind Fences?

CFD modelling may be applied to the wind fence design in a multitude of ways. The following provides a few of the ways that custom wind fence designers, engineers and corporate decision makers utilize CFD modelling.

- Optimizing Fence Design – Studies have shown that applying fluid dynamics through CFD modelling can predict wind velocity patterns and be highly beneficial in estimating actual wind speed reductions, optimal fence porosity and fence height 7. CFD modelling provides reliable information on effectiveness, wind and dust reduction and wind fence costs. For example, with CFD it is simple to answer questions such as “What reduction in wind fence effectiveness and cost would occur if the fence height is 20% less?”

- Fine Tuning Fence Design – A wind fence should be designed in a practical manner that does not disrupt work flow or operational requirements on a site in the area that it is protecting. CFD modelling allows for the evaluation of options and strategies to effectively manage site specific requirements for wind fences such as openings for vehicles, transport and material handling.

- Design Validation & Reassurance – A CFD simulation allows for the evaluation of fence performance and refine the design and materials used based on the results 8. CFD models validate how a fence will perform under a variety of conditions. Custom wind fences have a considerable initial investment cost. A well done CFD analysis provides reassurance for decision makers by demonstrating that the wind fence design solution will meet desired outcomes expectations (e.g. compliance with air quality standards).

- Return on Investment – CFD simulations of multiple design options at the early stages of the design process provide engineers fence specific information to refine structural design and fence material selection. A custom and optimally designed fence can reduce the amount of fencing and material required which significantly reduces costs while reducing material losses, improving dust control strategies and diminishing the need for additional measures for dust suppression.

- Modelling airflow patterns – CFD simulations are used to predict wind velocity distributions around wind fences which provide wind fence designers and engineers with information to predict air pressure loads on structures. CFD modelling is particularly useful on curved and irregular surfaces. CFD simulations may also be used to analyze shelter fence efficacy on solar panel arrays or to check design pressures in wind fence situations that are not covered by regular design rules. In some ways, this is superior to scaled models utilized in wind tunnel testing as potential discrepancies between scaled wind-tunnel experiments and real-world performance may factor in 6.

- Assessing Wind Fence Porosity – Using numerical methods found in CFD software to compute simulations, CFD can model the characteristics of fences and provide valuable information on how varying porous materials will affect flow behaviour, wind velocity 8 and dust control.

Choosing a CFD Partner

CFD modeling is extremely complex and requires specialty expertise to achieve optimal results. As the modeling itself requires the development of a highly detailed and extensive computational mesh (e.g. Tetrahedral) to provide a virtual environment for the purposes of visual representation and analysis, it is important to rely on highly trained professionals that have experience in CFD studies and applying the resulting data to practical applications. By engaging experts, you are ensured a comprehensive report that provides identification of the root cause of the concern and pragmatic solutions to keep costs down while achieving your objective. WeatherSolve engineers work collaboratively with the CFD experts to ensure that the simulations take into consideration key factors and that the data is analyzed and applied in a manner that validates and provides information to optimize design and performance. The takeaway here is to be mindful of companies presenting pretty graphs, the crux of the matter is how that information is gathered, analyzed and applied to your individual situation. Contact the WeatherSolve team for more information on our partners for CFD analysis regarding your unique dust suppression needs.

Application of CFD to a Real-World Scenarios

A custom wind fence was designed by the experts at WeatherSolve Structures to reduce dust at an ore processing facility in Saudi Arabia. CFD modelling was used to simulate site specific airflow and dust dispersion during windy conditions based on varying fence heights. The CFD study calculated effectiveness of 81% for the chosen design. The structure was duly built and a real world study was then conducted to determine the actual effectiveness of the fence and it was determined to be 85-91%.

Our next example takes us to Brazil where a mining facility required an effective dust mitigation. A custom wind fence was designed and CFD modelling was then conducted to determine the effectiveness of the fence. The CFD analysis conducted estimated that dust levels would be reduced by 78%. A real-world study was then initiated following wind fence construction to establish the actual value and it was found that the dust was reduced by 74%. This example demonstrates the accuracy and reliability of quality CFD studies as it pertains to wind fence design.

Summing it Up

Wind fences are essential in managing wind and dust in various industries, offering significant benefits such as improved operational efficiency, regulatory compliance, and reduced costs. To ensure these fences are effective, their design must account for multiple factors like topography, wind conditions, and materials. Computational Fluid Dynamics (CFD) plays a critical role in optimizing wind fence performance by simulating air flow patterns and providing insights into how various design elements, such as fence height and porosity, impact wind behavior and dust control. CFD modeling enhances the accuracy of wind fence design, leading to better outcomes and a higher return on investment, particularly in complex or site-specific environments.

References and Additional Reading Material:

- “Using Agglomerative Dust Suppression and Wind Breaks for Fugitive Dust Abatement” Australasian Mine Safety Journal April 17, 2019 https://www.amsj.com.au/using-dry-fog- dust suppression-and-wind-breaks-to-control-dust/ Accessed Sept 26, 2024

- “Computational Fluid Dynamics” https://en.wikipedia.org/wiki/Computational_fluid_d namics Accessed December 16, 2024

- “Navier-Stokes equations” https://en.wikipedia.org/wiki/Navier%E2%80%93Stok s_equations Accessed December 16, 2024

- Sadrehaghighi, I. “Unstructured Meshing for CFD” CFD Open Series. Accessed December 16, 2024

- “Discretization” https://www.dictionary.com/browse/discretization Accessed December 16, 2024

- Liu, B., Qu, J., Zhang, W., et al. “Numerical evaluation of the scale problem on the wind flow of a windbreak”. Scientific Reports October 2014. Accessed December 16, 2024.

- Hong, S., Lee, I., Hwang, H., “Modelling Wind Velocity Patterns for Windbreak Fence Design”. International Conference of Agricultural Engineering. July 6 – 10, 2014. Accessed December 16, 2024.

- Xu, Y., Mustafa, M., Knight, J., et al. “3D CFD Modeling of Air Flow Through a Porous Fence.” 4 th IEEE Conference on Cognitive Infocommunications. December 2-5, 2013. Budapest, Hungary. Accessed December 16, 2024.

Claire Cowie is a seasoned Quality Assurance Manager with over two decades of experience in healthcare and manufacturing. Her career began in pharmacy, where she led teams and honed her skills in quality management systems. As she transitioned to the manufacturing sector, her unique background combines a deep understanding of policy and quality assurance with a keen eye for quality control.

Claire has been instrumental in implementing and cultivating a comprehensive quality control program within WeatherSolve Structures. She has successfully integrated her pharmaceutical background with manufacturing best practices, particularly in areas such as Good Manufacturing Practices (GMP) and ISO 9001 standards. Her unique blend of experience continues to drive innovation and excellence in her role.