Employee Health & Safety – ROI’s of a WindFence

Industrial dust poses significant risks to workplace safety and health, contributing to serious injuries, medical conditions, and fatalities. Research indicates that just one day with “dust precipitation” increases workplace injuries by 1.2% 1 . Given the millions of workplace injuries reported worldwide each year, this 1.2% increase represents a substantial concern that must be addressed as approximately 450,000 workplace deaths annually are attributed due to air pollution 2.

Dust is an omnipresent issue in many industries that requires a vigilant and detailed management strategy to overcome. Businesses are on the lookout to implement technologies and other approaches to reduce dust and protect the health and safety of their employees. Of the many available dust suppression methods currently available, wind fences stand out as an effective way to improve health and safety by helping to mitigate the negative implications of dust. This article will explore the various types of dust, how dust affects health and safety, and how a custom wind fence can protect workers and positively impact your organization’s bottom line. Implementing a wind fence yields a notable return on investment (ROI).

What is Dust?

Dust is defined by the International Standards Organization as “small solid particles, conventionally taken as those particles below 75 microns in diameter, which settle out under their own weight but which remain suspended for some time 9 ”. Note that a micron also referred to as a µm is a metric unit of length where 1µm equals 0.001mm or 1/25,400 of an inch. The World Health Organization refers to dust as “solid particles ranging in size from below 1µm to around 100µm, which may be or become airborne, depending on their origin, physical characteristics and ambient conditions 10 .” For context, the thickness of a human hair is approximately 60µm 20 and particles that are visible to the naked eye hover at around 40µm.

Dust can be categorized as either respirable or inhalable. Inhalable dust is visible dust that is generally 10µm – 100µm in size 1 and may cause illness or damage to the upper respiratory tract. Respirable dust contains particles which are less than 10µm in size and can be inhaled deep into the lungs 1 and alveoli. These respirable particles are not visible to the naked eye.

Dust may additionally be categorized based on chemical composition: inorganic and organic 11 . Inorganic dust is derived from grinding or breaking up materials such as rock or metals and includes other potentially harmful materials which may consist of silica, coal, natural stone, tungsten, aluminum, or beryllium 12. Organic dust, on the other hand, may arise from handling plant or animal-based products such as wood or grain. Due to their derivation, organic dust may also contain fungi and other microbes or endotoxins which can cause detrimental health effects 11 . Based on chemical composition, inorganic dust tends to be more dense than organic dust, although there may be exceptions dependent on the particular materials involved.

Density, particle shape and particle size affects how the dust behaves in the air. Particles that are smaller in size require less dust lift off velocity to become airborne than that of larger particles. Larger, denser, and rounder particles generally remain airborne for a shorter period of time compared to smaller particles due to their weight. Equally, particles that are shaped like a piece of paper (as an extreme example) lift more easily that something smooth and round like a bowling ball.

Mineral, metallic, organic, and biohazards are examples of dust commonly found in an industrial setting. These types of dust may be generated by work-related processes and have various impacts on employee health and safety based on their aerodynamic behaviour. Dust is released or generated whenever workplace activities require handling of materials 2 by transferring, moving, mixing, conveying, and other tasks, or when wind or other environmental factors are at play.

How Does Dust Affect Health and Safety?

Dust affects health and safety in a myriad of ways. With regard to health consequences, the way in which dust impacts the body is dependent on the type, size, composition, and concentration of the particulate matter, in addition to the length of exposure 15 . As discussed above, inhalable dust is 10µm – 100µm in size and tends to primarily impact the upper respiratory tract. Exposure to inhalable dust may exacerbate pre-existing medical conditions such as asthma, cardiovascular disease and chronic obstructive pulmonary disease as well as cause skin and eye irritation. With prolonged exposure, it is suggested that inhalable dust can lead to chronic breathing and lung issues as well as heart disease 13 . Inhalable dust has also been shown to increase the risk of gastric cancer from workplace exposure 16 . Respirable dust (particles less than 10µm in size) pose a serious threat to personal health as these particles are small enough to enter the lower respiratory tract and lungs. Breathing in respirable dust may lead to life-threatening illness such as silicosis, lung cancer, and kidney disease 14 .

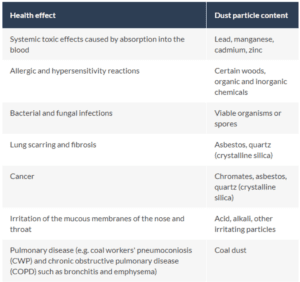

The table below provides examples of dust particle content and their associated health risks.

Source: https://www.business.qld.gov.au/industries/mining-energy- water/resources/safety health/mining/hazards /dust /health-safety

Safety concerns resulting from industrial dust also require careful consideration when determining an effective dust management strategy. Dust negatively impacts site operations through the creation of combustible dust (especially in enclosed buildings) and impacting workplace safety.

When considering options to minimize the impacts of dust on employee health and safety in various industrial settings, wind fences offer a viable and effective solution.

What is a Wind Fence?

A wind fence is an engineered porous barrier that is erected to reduce wind speeds and suppress dust. Wind fences have two modalities in which they function: as an upwind fence or, conversely, as a downwind fence. Upwind fences reduce the velocity of incoming wind while allowing a small amount of wind to pass through. This reduces dust movement and effectively reduces the speed of the wind on the leeward side of the fence by 50 – 80% (with a quality well designed wind fence). On the other hand, a downwind fence works as a catch fence to capture dust that is still in motion. As wind patterns and weather changes, an upwind fence may become a downwind fence and vice versa.

There are many considerations when it comes to implementing and designing a wind fence. Wind speeds and directions are critical as they factor in the ideal placement and required height for a wind fence. The type and coverage of the material also plays a role in the effectiveness of the wind fence. For instance, a downwind fence that is constructed with a mesh fabric having openings greater than 25mm or with gaps under the fence render a downwind fence virtually ineffective. WeatherSolve Structures have proven the effectiveness of our tightly meshed and woven porous fabric both through extensive wind tunnel testing and in real life applications worldwide.

How Can a Wind Fence Improve Health and Safety Outcomes?

1. Enhanced worker safety

Dust generated by stockpiles, wind, and site operational activities can settle on surfaces creating slippery conditions that pose a serious slip and fall hazard to workers. Dust that falls on machinery can migrate into engines and clog filters causing costly and potentially dangerous equipment malfunctions. It has also been shown that airborne particulate matter with a diameter less than 44µm can reduce visibility thereby greatly increasing the risk of a workplace accident 4,17. These negative occurrences impact worker safety, labour costs and the company’s bottom line.

Combustible dust found in industries such as mining, agriculture, and manufacturing poses a hidden danger and a significant threat to personnel and operations. Combustible dust is defined as “finely divided solid particles that are prone to ignition when suspended in the air 18 ”. Combustible dust occurs when fine particles (typically smaller than 420µm 18 ) reach a certain concentration level and are exposed to an ignition source, resulting in a rapidly spreading fire or in some cases an explosion. The resulting fire or explosion can lead to extensive damage,

injury, and in some cases, fatalities.

Effective dust control strategies can minimize dust accumulation, resulting in safer walkways and work surfaces. Reduced dust buildup also lowers the risk of combustible dust improving worker safety. A quality well-designed wind fence can drastically reduce dust on a site leading to a cleaner and safer working environment while enhancing worker safety outcomes.

2. Improved health outcomes

The health effects of dust exposure are devastating and primarily affect the respiratory system. According to the Canadian Centre for Occupation Health and Safety (CCOHS), the main dust-related illnesses that affect workers are 3:

- Lung cancer

- Silicosis

- Chronic Obstructive Pulmonary Disease (COPD)

- Asthma

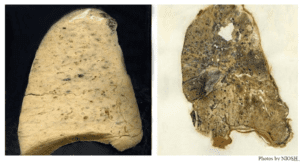

The image below shows a normal lung on the left and a silicotic lung on the right.

Some of these diseases have a sudden onset, while others may take years to develop. Regardless, they all have a detrimental impact on personal health. Fugitive dust is created in large amounts on industrial and mining sites where there are strict environmental regulations in place to help protect workers. With occupational diseases costing over $26 billion dollars worldwide 5 each year, controlling airborne dust is critical in preventing workplace-related illness.

Well-designed wind fences generally reduce fugitive dust to 1/8 th that of an unprotected situation. They act to physically reduce airborne particulate matter through reducing wind speed and trapping fugitive dust without the use of potentially harmful chemicals and sprays or other consumables. In addition, health outcomes amongst workers are improved through the improvement of air quality and reduction of airborne particulate matter. In areas where organic dust is prevalent, wind fences may also impact the level of airborne allergens such as pollen.

3. Protection from Extreme Weather Conditions

Construction and other industrial workers are often exposed to extreme weather conditions such as high winds and extreme temperatures while on the job. The U.S. Bureau of Labor Statistics estimates there were 55 deaths in the U.S. in 2020 attributed to weather conditions 7. While working in high winds, there are many potential hazards that workers may encounter 6 :

- Eye injury due to dust and debris

- Injuries and death due to falls

- Skin damage

- Broken power lines

- Reduced visibility

- Equipment failure

- Collapsing building, scaffolding etc…

- Tools and equipment blown off elevated platforms and scaffolding

- Sprains and strains due to moving objects

Custom wind fences offer a viable solution to help shield workers from these hazardousconditions and prevent work related accidents and fatalities. A custom wind fence reduces wind velocity by at least 75% which greatly diminishes the impact that high winds have on the protected area. In fact, gusts are effectively stopped which improves both health and safety outcomes. Many jurisdictions have regulations regarding protecting workers in windy conditions. For example, the Occupational Health and Safety Association “considers wind exceeding 30-40mph” as hazardous “unless the employer takes precautions to protect employees from the hazardous effects of the wind 19 ”. Wind fences create a stable working environment that protects workers from high winds allowing them to work in less dangerous conditions.

Workplace heat stress is another environmental hazard that workers might encounter on the job. In the U.S., heat-related exposure is estimated to result in $100 billion annually in reduced worker productivity 8 . Heat stress impacts not only the economy and worker health but also affects a company’s operating costs and overall efficiency. A custom wind fence constructed from porous fabric offers dual benefits: it shields against high winds and provides shade, helping to reduce the effects of high temperatures.

4. Enhanced Operation Stability

By protecting equipment from wind and dust damage, wind fences help ensure that machinery operates reliably, reducing the risk of accidents caused by equipment failure. This contributes to a safer work environment by minimizing the likelihood of operational disruptions. In one real-world example, a site was struggling with the hazard of dump trucks being blown over when dumping during high winds. The solution was to install a custom-designed wind fence to mitigate the negative impact on safety and operations.

Insights

In summary, dust poses severe risks to both workplace safety and health, leading to increased injuries, equipment damage, and significant economic costs. The evidence underscores the critical need for effective dust control measures, especially in environments prone to high dust and extreme weather conditions.Custom wind fences present a comprehensive solution by addressing multiple safety and health concerns. They significantly reduce wind speed and capture airborne dust, creating safer walkways and work surfaces while protecting valuable product and machinery from damage or erosion making their ROI considerable. This results in fewer accidents, improved health

outcomes, and enhanced operational stability. Additionally, wind fences provide protection fromnextreme weather conditions and mitigate heat stress, further contributing to a safer and more efficient work environment. By investing in custom wind fences, organizations not only enhance worker safety and health but also realize substantial long-term savings and operational benefits. The integration of wind fences into your safety strategy ensures a cleaner, safer, and more productive workplace, underscoring their value as a proactive investment in both employee well-being and operational efficiency.

References &; Reading Material:

1. Martinez, I., Hattemer, B. “Dust to dust: How natural air pollution induces work accidents” European University Institute https://lafonte.eui.eu/2024/05/09/dust-to-dust-how-natural-air-pollution-induces-work-accidents/ Accessed August 8, 2024

2. World Health Organization https://www.who.int/news/item/17-09-2021-who-ilo-almost-2-million-people-die-from-work-related-causes-each-year Accessed August 8, 2024

3. CCOHS Health and Safety Reporthttps://www.ccohs.ca/newsletters/hsreport/issues/2016/03/ezine.html Accessed August 8, 2024

4. Anmilah, F., Gopaldasani, V, MacPhail, C., et al. “A systematic review of the effectiveness of dust control measures adopted to reduce workplace exposure” Environ Sci Pollut Res Int 2023: 30(19): 54407-54428 https://www.ncbi.nlm.nih.gov/pmc/articles/PMC10121514/ Published online 2023 Mar 25. Accessed August 8, 2024.

5. Goldyn, S., Condos, R., Rom, W. “The Burden of Exposure-Related Diffuse Lung Disease” Semin Respir Crit Care Med. 2008 Dec; 29(6): 591-602. Published online 2009 Feb 16.https://www.ncbi.nlm.nih.gov/pmc/articles/PMC3647468/ Accessed August 8, 2024.

6. CCOHS “Weather – High Winds”https://www.ccohs.ca/oshanswers/safety_haz/weather/high_winds.html Accessed

August 8, 2024

7. U.S. Bureau of Labor Statistics “Workplace deaths from weather and atmospheric conditions” June 3, 2022 https://www.bls.gov/opub/ted/2022/workplace-deaths-from-weather-and-atmospheric-conditions.htm Accessed August 8, 2024

8. Fulcher, J., “The Cost of Inaction” Public Citizen https://www.citizen.org/article/heat-stress-the-cost-of-inaction/ Accessed August 8, 2024

9. ISO 4225 https://www.iso.org/obp/ui/#iso:std:iso:4225:ed-2:v1:en Accessed Sep 23,2024

10. World Health Organization “Hazard Prevention and Control in the Work Environment: Airborne Dust” December 1999 https://www.who.int/publications/i/item/WHO-SDE-OEH-99-14 Accessed September 23, 2024

11. Canadian Centre for Occupational Health and Safety “Chemicals and Materials” https://www.ccohs.ca/oshanswers/chemicals/lungs_dust.html Accessed Sept 23, 2024

12. Queensland Government “Notifiable Dust Lung Diseases”https://www.qld.gov.au/health/staying-healthy/workplace/notifiable-dust-lung diseases#:~:text= Examples%20of%20inorganic %20dust% 20include,%2C% 20cobalt%2C%20aluminium%20and%20beryllium. Accessed September 24, 2024

13. Queensland Government “Airborne dust and health effects”https://www.qld.gov.au/health/staying-healthy/environmental/after-a-disaster/bushfires/airborne-dust-and-health-effects Accessed September 24, 2024

14. Occupational Safety and Health Administration “Silica, Crystalline Health Effects”https://www.osha.gov/silica-crystalline/health-effects#:~:text=Breathing%20in%20very%20small%20(%22respirable,COPD)%2C%20a

nd%20kidney%20disease. Accessed September 24, 2024.

15. Queensland Government “Health and Safety Effects of Dust”https://www.business.qld.gov.au/industries/mining-energy-water/resources/safety-health/mining/hazards/dust/health-safety Accessed September 24, 2024.

16. Kang, M., Jung, J., Koo, J., et al. “Increased risk of gastric cancer in workers with occupational dust exposure” Korean J Intern Med. 2021 Mar; 36(Suppl 1): S18-S26. Published online 2020 May 7. https://www.ncbi .nlm.nih.gov /pmc/articles/PMC8009167/Accessed September 24, 2024.

17. Ontario Stone, Sand & Gravel Association “Dust Management at Pits & Quarries” June 2021 https://ossga.com/multimedia/2021-06-04-132019- 32717/dust_management_gravel_facts_sheet_june_2021_.pdf Accessed September 24,2024.

18. Cloney, C., Barrett, J. “An Ultimate Guide to Combustible Dust: What It Is & How to Manage it” Dust Safety Science Aug 13, 2024 https://dustsafetyscience.com/what-is-combustible-dust/ Accessed September 24, 2024

19. https://www.osha.gov/laws regs/regulations/standardnumber /1926/1926.968#:~:text=Note %20to%20the %20definition%20of%20%22high%20wind%22%3A%20The%20Occupational,criteria%2C%20unless%20the%20 employer%20takes Accessed Oct 9, 2024

20. Cecala, A., O’Brien, A.D., Schall, J., et al. “Dust Control Handbook for IndustrialMinerals Mining and Processing” Second Edition March 2019