A number of things are taken into consideration when planning the layout of a windbreak. This page introduces the main concepts.

Wind Direction

Wind direction is the number one consideration in designing an effective windbreak layout. The information can come from local knowledge or by measurement. The best sources are government agencies such as the National Climatic Data Center in the USA for long term data from major centers. This should then be adjusted to take account of differences in topography between the centre and the site. Short term measurements of wind at the site can be used to calculate the correction factors required.

If local knowledge is to be used, take the perspective of the provider into account. For example, a loader driver may be convinced the wind comes predominantly from the South (say), but not realize that the area of the yard he generally works in is partially shielded from the West. As a result the South wind he sees is actually a South-westerly wind being deflected around the building.

To resolve disputes, one excellent method is to make up some stakes about 4ft (1.2m)long with a 2ft (0.6m) long ribbon tied to the top. Position the stakes at key points, make up a map of the site and record as follows on windy days.

- Direction: What direction is the ribbon pointing?

- Strength: What angle is the ribbon hanging at? The nearer to horizontal, the faster the wind is blowing.

- Turbulence: How much is the ribbon flapping? More turbulent wind tends to pick up more dust.

Armed with this wind information the windbreak can be positioned so that it’s effectiveness is maximized. This means positioning it so that it is as close as possible upwind from the worst sources of dust, and that accesses and gaps are generally located in non-windy spots.

Access

If it is not possible to avoid having openings along the exposed face of a windbreak, doorways and curtains can be used. In general, though they should be avoided unless the opening is only needed once every few weeks.

Better solutions are as illustrated below. The front fence need only be the height of the opening (typically 20ft (6m)).

Height

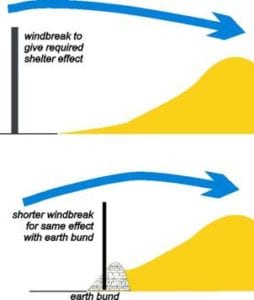

The height of the fence is governed by the height of the items to be sheltered and the distance that they will be from the fence. To give a very typical example, to shelter a conveyor head dropping material on a stockpile, the fence generally needs to be as high as the conveyor and not more than 3 times the height of the conveyor upwind from it.

Stockpiles built by bulldozers and loaders have a tendency to develop flat side-slopes to enable the drivers to go up and down them. When this happens, the pile gets very spread out and it may be difficult to get the windbreak close enough to the conveyor-head.

One solution to this is to build a retaining wall or bund as shown below. It forces a slightly different driving pattern to spread and retrieve the material, but should still be operable. The benefit can be a significant saving in the height of fence required.

Layout

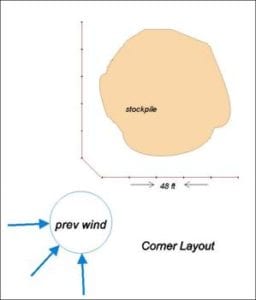

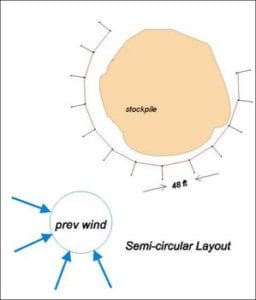

Windbreaks primarily operate as deflectors of the wind. For long fences the deflection is mostly over, for short fences, mostly around. When protecting moderately circular things such as stockpiles, short fences work best. The drawings below show two ways of arranging such fences.

The first one has two straight legs and suits winds coming very predominantly from one quadrant of the compass. Note the truncated corner. This is to control vortice-shedding. Vortices are turbulent spirals of wind which tend to spin off sharp corners that point directly into the wind.

The second arrangement is set up as a semi-circle. The braces on the poles are drawn outwards, but they could point inwards too. This layout is structurally very efficient when the curve in the fence is sharp enough so that the tension in the cables supporting the cloth balances the tension in the outward brace or guy.

Structure

There are a number of different pole types. Not every pole suits every layout. The drawings below show the main variations.

Snow

The wind fence will also affect the snowdrift patterns around it.

Generally, when fences are up to 15 times longer than they are high, they will deflect blowing snow to the side. This will be the case with most near-circular stockpiles. In fact the fence layouts drawn above are very similar to layouts used for livestock-shelter snow fences.

For longer straight fences there can be a build-up of snow in front of the fence. If this would be inconvenient to remove, a more porous bottom section of the fence may need to be incorporated to allow the snow to pass through in the same way that snow passes through a snow-fence.

Note that this would then cause the snow to be deposited on the stockpile behind the fence.