The Strategic Advantage of Custom Wind Fences

In the pursuit of managing and reducing dust emissions on industrial sites, effective dust control strategies are critical for ensuring operational efficiency and protecting employee health and safety. Of the many dust management methods available, custom wind fence structures have consistently demonstrated their effectiveness as a tool to fight against fugitive dust through reducing wind velocity and preventing the uptake of particulate matter in the protected zone.

Unlike some other dust suppression methods, wind fences act as a physical barrier to reduce wind speeds and prevent dust from becoming airborne. The ability to customize a wind fence based on topography, environment, and specific site needs makes them a superior choice for dust control in a variety of settings.

In this article we will explore the fundamentals of wind fences; examining their benefits and how they can be effectively incorporated into current site operations and dust management systems. We will delve into cost considerations, maintenance requirements, and examples of wind fence integration to ensure you are fully equipped to determine the best solution for your dust suppression needs.

Introduction to Dust Control Solutions

From foam suppressants and surfactants to wind fences and fog systems, the list of dust control methods is extensive and weeding through the endless information on which option is best suited can be a time consuming and daunting task. So, what are the main dust suppression options available on the market? Here is a list of a few common solutions.

1. Custom wind fences

A specifically engineered and designed structure that acts as a barrier to alter wind patterns and slow wind speeds to protect a specific area.

2. Fogging Systems

Strategically placed specialized nozzles that use compressed air to disperse water mist into the air and reduce dust through the process of agglomeration.

3. Foam Suppression

Foam suppression uses a specially formulated foam as a coating to manage and reduce airborne dust.

4. Surfactants

Surfactants are chemicals that are added to water to reduce the surface tension of water. The surfactant/water mixture and is then sprayed to reduce the amount of airborne dust through agglomeration.

Fundamentals of Wind Fences

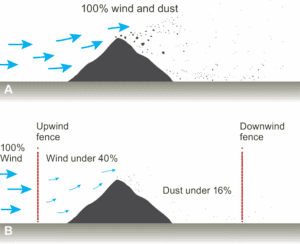

The primary function of a wind fence is to reduce wind velocity in a specific area in order to protect it from the impacts of strong winds. Wind fences are constructed by erecting a porous material to act as a barrier and mitigate dust in a plethora of environments such as agriculture, mining, manufacturing, and construction. The porous barrier reduces the velocity of wind and significantly diminishes dust by two key modes: upwind fences and downwind fences. Upwind fences reduce the velocity of incoming winds thereby preventing dust particle uptake, whereas downwind fences “catch” dust that is still in motion. As wind directions change, an upwind fence may become a downwind fence, and vice versa. In an unprotected situation, wind blows up the side of a stockpile and causes particulate matter to become airborne. The smaller the particle, the further it spreads. Some particles “can travel hundreds or thousands of miles and influence the air quality of regions far from the original source”1.

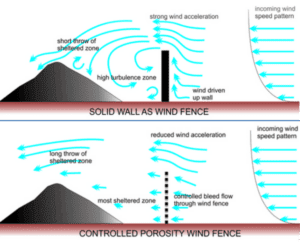

So how does a wind fence work? A wind fence slows the wind while allowing a small amount of wind to pass through the porous barrier effectively equalizing the differential pressure on either side of the barrier2. The result is a “sheltered zone” on the leeward side of the fence without the turbulence and wind eddies that are seen with the use of a solid structure. The size of the area that is protected is dependent on the height and design of the wind fence. The image below illustrates how wind interacts with a solid barrier versus a wind fence.

For a well-designed wind fence with controlled porosity, wind speeds can be reduced by approximately 50-75% on the leeward side. Factors such as wind fence material, fence design, site topography, fence orientation, and size of the area to be protected must be considered to optimize results.

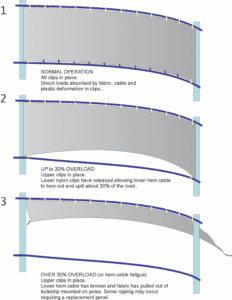

The industry experts at WeatherSolve Structures recommend implementing a tightly meshed woven fabric made from durable high-density polypropylene or polyethylene fabric used in conjunction with a stress-release clip system to provide effective and reliable protection from winds and extreme storms. The innovative design of the stress-release clip system helps to protect the integrity of the structure from high loads experienced during extreme wind conditions. Highly specialized clips operate like a zipper to release the bottom of the wind fence panel during these events, thus reducing the overall load and preventing structural failure. The top of the panel remains clipped in place greatly reducing the risk of any safety issues. Once the storm has passed, the bottom clips are quickly and easily replaced and the fence is up and back in action again!

Benefits of Wind Fences for Dust Control

There are a variety of benefits that wind fences offer in dust suppression management. Here is a list of some of the benefits that a custom wind fence can offer:

1. No operational downtime

A wind fence is always operational as it lacks mechanical parts and does not require consumables or workers to operate.

2. No water or chemicals required

A wind fence does not require water or chemical additives which may result in a chemical reaction with some materials.

3. Improved dust control

A well-designed custom wind fence can reduce fugitive dust to less than 1/8 that of an unprotected situation. Upwind fences reduce the amount of dust particles that are kicked up and become airborne. Downwind fences capture dust that already in motion. The result is improved air quality, visibility, health and safety, and a reduction in valuable product erosion.

4. Increased operational efficiency

Less dust on an industrial site means less downtime required for equipment failures and employee absenteeism due to dust-related issues.

5. Regulatory compliance

With increasingly strict environmental protection regulations becoming a requirement in many jurisdictions worldwide, wind fences offer a viable solution to control fugitive dust and comply with air quality standards.

6. Reduced maintenance costs

Investing in a wind fence reduces the need for consumables such as chemical treatments or water, thus reducing the high maintenance costs that are seen with other dust management solutions. Once a wind fence is in place it requires very little effort to maintain leading to long-term cost savings.

7. Protecting Product

High winds can cause erosion and loss of stored product on mining sites. Protecting stockpiles from wind prevents high-value product from blowing away resulting in huge loss of profit. The amount of valuable material in dust on a mining site is typically three or more times higher than what is found in the raw mined material making wind fences an obvious choice for the prevention of product loss.

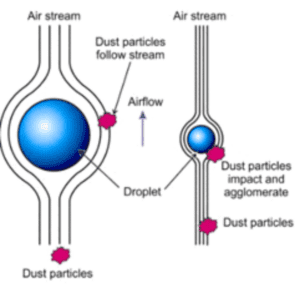

Integrating a Wind Fence into Existing Dust Control Strategies

Integrating a wind fence into an existing dust management plan has shown to improve the effectiveness of other dust control methods such as dry fog systems. Dry fog dust collection systems use specialized nozzles to create and disperse a cloud of atomized water droplets that are approximately the same size as the dust particles3. The fog interacts with the dust particles and suppresses the dust through a process called agglomeration. Agglomeration is defined as “the act or process of gathering into a mass5”. If the water droplet diameter is larger than the dust particles, the dust particles will be caught up in the air stream surrounding the water droplet and not come into contact with it5. With dry fog systems, the water droplet diameter is roughly the same as the dust particle diameter allowing for contact and agglomeration resulting in the particle falling to the ground under the extra weight.

Source: https://www.syklone.com/mm5/graphics/00000001/PDF_files/reference/NIOSH_DustControlHandbook_RI_9689.pdf

In order for a dry fogging system to achieve optimal efficiency, an enclosure may be required4. The enclosure provides sufficient time for the small water droplets and dust particles to come into contact with each other and agglomerate airborne dust. A wind fence has been shown to improve the effectiveness of dry fog control systems especially in areas where ROM bins aka dump hoppers are exposed2.

Dust generated in enclosed buildings found on industrial sites cannot escape and many businesses utilize fog systems in an attempt to control dust at the source. In many instances, these buildings lack the necessary airflow resulting in an extremely unpleasant and potentially dangerous environment for workers. Should some of the walls be replaced by a wind fence, this allows for air exchange and improved dust suppression creating a more comfortable environment.

In the world of sports, wind can cause advantages and disadvantages. Take, for example, rowing. Wind can affect one rower positively, while another negatively. Integration of a wind fence stabilizes the wind creating an equal playing field. A study on wind fences installed for the 2022 Winter Olympic and Paralympic games in Beijing was conducted to determine their effectiveness reducing the impact of wind on the outcomes of alpine skiing. The study determined that the wind protection effect for alpine skiing was significant9.

Wind fences also offer an economic benefit to solar panel field outputs and operating costs. It has been shown that the accumulation of dust on a solar panel can reduce the photovoltaic (PV) output by up to 30% in one month6. Solar panel operators often angle or fold the panels to reduce the effects of dust, especially in dry, arid and windy areas. In addition, wind induced vibration due to wind load is a major cause of solar panel support failure7. Wind fences can effectively reduce wind speeds by up to 75%, protecting both the solar panel structure and preventing the loss of PV output due to dust accumulation. It is estimated that integrating a wind fence to protect solar panels could save approximately 1% of the solar plant capital cost or CAPEX8.

Cost Considerations

The initial investment requirements for a custom wind fence can vary significantly dependent on the size and type of project. Here is a breakdown of some of the costs associated with implementing a custom wind fence:

- Design and engineering costs

- Manufacturing costs

- Installation costs

- Site preparation and permits costs

- Contingency costs

Although the initial cost of a custom wind fence may be substantially higher than those found with other dust control solutions, their low maintenance and operational costs, durability, and high efficiency make them a long-term solution and cost-effective answer to your dust suppression needs.

Maintenance Requirements

In general, custom wind fences are a “set it and forget it” solution to dust control. They do not consume costly commodities such as adjunctive chemicals, oil, or gas and require little maintenance. A WeatherSolve custom wind fence utilizes specialized fabrics that are resistant to dust build up. In addition, the wind fence panels act similarly to a doormat where dust is easily shaken out. Custom wind fences are largely maintenance free but should cleaning be required (e.g. aesthetic reasons), the following applies:

Preferred Method for Cleaning:

The preferred method of cleaning a wind fence is to not to clean it at all. The wind will take care of any dust that gets trapped in the fence. Remember that a dusty fence tends to be more effective at stopping more dust!

Alternative Method for Cleaning:

Pressure washing – use a wide spray nozzle at a 20-degree angle and keep the wand at a safe distance.

Key Takeaways

Integrating wind fences into your dust control strategy offers a multifaceted approach to managing dust emissions effectively. By serving as a physical barrier, custom wind fences can significantly reduce wind speeds, minimize dust dispersion, and enhance overall operational efficiency. Their tailored design ensures that they meet the specific needs of each site, making them a versatile and powerful tool for industries plagued by dust issues.

While the initial investment in custom wind fences might seem higher than partial solutions, the long-term benefits—including reduced maintenance costs, improved durability, and enhanced dust control—justify the expense. For industries facing high wind conditions, dust-prone environments, or stringent regulatory requirements, custom wind fences provide a targeted and efficient solution that can lead to substantial improvements in operational conditions and regulatory compliance.

By understanding the unique advantages and applications of wind fences, businesses can make informed decisions to integrate this effective dust control solution into their overall dust management strategies, ultimately leading to a cleaner, safer, and more efficient work environment.

References and Reading Materials: Top of Form

- United States Environmental Protection Agency “What is Particle Pollution” https://www.epa.gov/pmcourse/what-particle-pollution Accessed Sept 26, 2024

- “Using Agglomerative Dust Suppresion and Wind Breaks for Fugitive Dust Abatement” Australasian Mine Safety Journal April 17, 2019 https://www.amsj.com.au/using-dry-fog-dust-suppression-and-wind-breaks-to-control-dust/ Accessed Sept 26, 2024

- https://www.raringcorp.com/technologies/adstm-dry-fog Accessed Sept 26, 2024

- https://www.raringcorp.com/technologies/wind-fence Accessed Sept 26, 2024

- Cecala, A., O’Brien, A., Schall, J., et al. “Dust Control Handbook for Industrial Minerals Mining and Processing”. January 2012. https://www.sy-klone.com/mm5/graphics/00000001/PDF_files/reference/NIOSH_DustControlHandbook_RI_9689.pdf Accessed Sept 26, 2024.

- MIT News – How to clean solar panels without water. https://news.mit.edu/2022/solar-panels-dust-magnets-0311#:~:text=But%20the%20accumulation%20of%20dust,is%20essential%20for%20such%20installations. Accessed Oct 15, 2024

- Nan, B.; Chi, Y.; Jiang, Y.; Bai, Y. Wind Load and Wind-Induced Vibration of Photovoltaic Supports: A Review. Sustainability2024, 16, 2551. https://doi.org/10.3390/su16062551

- Hamed, I., AbdelGawad, A., Ragab, R., Computational study of reducing wind loads on solar-power plants using windbreaks. Journal of the Brazilian Society of Mechanical Sciences and Engineering. 46(6) May 2024 https://www.researchgate.net/publication/380752354_Computational_study_of_reducing_wind_loads_on_solar-power_plants_using_windbreaks

- Fu, Z., Li, Q. “Study of Wind-Proof Effect and Stability of Windbreak Fence in Alpine Skiing Centre” Sustainability 2023, 15(4), 3369; https://doi.org/10.3390/su15043369

Claire Cowie is a seasoned Quality Assurance Manager with over two decades of experience in healthcare and manufacturing. Her career began in pharmacy, where she led teams and honed her skills in quality management systems. As she transitioned to the manufacturing sector, her unique background combines a deep understanding of policy and quality assurance with a keen eye for quality control.

Claire has been instrumental in implementing and cultivating a comprehensive quality control program within WeatherSolve Structures. She has successfully integrated her pharmaceutical background with manufacturing best practices, particularly in areas such as Good Manufacturing Practices (GMP) and ISO 9001 standards. Her unique blend of experience continues to drive innovation and excellence in her role.